Printing the Future: FUJIFILM Dimatix Creates More Than Just Graphics

Today, printing is no longer just for paper. Advances in printhead technologies now allow the printing of images and intricate patterns onto just about any material you can think of – from textiles to tiles.

And the possibilities don’t stop there – with FUJIFILM’s latest printhead innovations also exploring the potential of printing flexible electronic sensors – a game-changing technology that is bridging the gap between printing and electronics, and pioneers the way forward in wearable devices.

Exploring FUJIFILM Dimatix Technology: Revolutionising Industrial Inkjet Printing

In the realm of industrial inkjet printing, FUJIFILM Dimatix stands as a beacon of innovation. Specialising in piezoelectric drop-on-demand inkjet printheads, Dimatix has consistently pushed the boundaries of what’s possible in digital printing technology. This article delves into the core technologies, applications, and advancements that define FUJIFILM Dimatix’s impact on the printing industry.

The Genesis of Dimatix Technology

FUJIFILM Dimatix, a subsidiary of the FUJIFILM Corporation, has its roots in the development of precision inkjet technologies. The company’s expertise lies in creating printheads that deliver exceptional dot placement accuracy, channel-to-channel uniformity, and high-frequency productivity. These advancements have paved the way for high-quality, high-speed digital printing solutions across various industries.

Key Technologies and Innovations

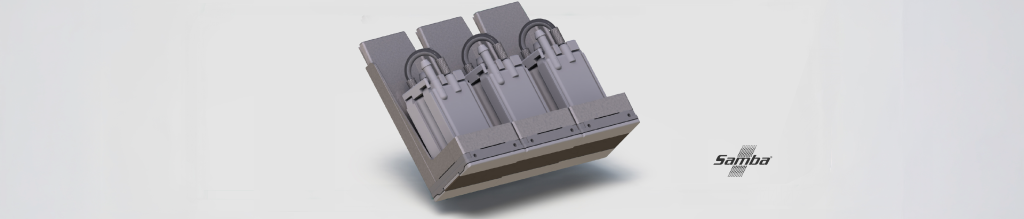

Samba™ Printheads

The Samba™ printhead is a testament to Dimatix’s commitment to excellence. Featuring 2,048 individually-addressable nozzles, it offers a native resolution of 1200 dpi and a native ink drop size of 2.4 picoliters. This configuration allows for outstanding print quality, capable of jetting a wide range of fluids, including UV curable and aqueous inks. The unique parallelogram design of the Samba nozzle plate enables simplified stitching, resulting in a very narrow, 1200 dpi printbar.

Additionally, the RediJet™ continuous ink recirculation system ensures quick priming, minimal ink waste, and greater reliability, while VersaDrop™ technology further enhances performance by allowing multiple fixed drop sizes in binary mode and grayscale capability from one printhead, without compromising productivity.

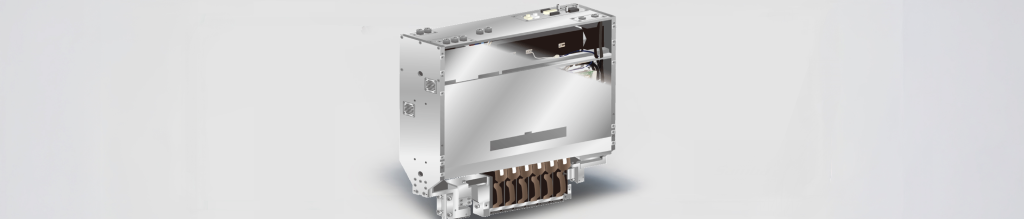

Samba JPC™ UV Inkjet Modules

To facilitate seamless integration into printing systems, Dimatix introduced the Samba JPC™ UV inkjet modules. These modules are designed for system designers and integrators, enabling them to minimize the product development cycle of 1200 dpi single-pass inkjet printers.

The modules support high image quality, reliability, and uptime, making them ideal for various UV ink print applications. Components include a UV ink printbar, head cleaner, anti-collision sensor, timing control unit, and image optimisation software, all housed in a compact design that eliminates the need for external fluid management tools.

SKYFIRE® SF600 Printheads

Unveiled at Drupa 2024, the SKYFIRE® SF600 printhead represents the next generation of Dimatix’s inkjet technology. Built upon the company’s renowned silicon Micro Electro-Mechanical Systems (Si-MEMS), the SF600 delivers high productivity and versatility for both single-pass and scanning solutions. It features a resolution of 600 dpi with a drop size range of 5–25 picoliters and is equipped with an integrated trimming heater and temperature sensor for optimal ink handling.

The printhead’s design includes REDIJET® coating, enabling reliable jetting of a range of aqueous, solvent, oil, and UV curable inks. With a jetting capacity of 11 grams of ink per square metre per colour at over 130 meters per minute, the SF600 is poised to meet the demands of high-speed, high-quality printing applications.

Applications Across Industries

FUJIFILM Dimatix’s inkjet technologies have found applications across various sectors, including:

• Commercial Printing: Delivering high-quality prints for marketing materials, brochures, and catalogues.

• Packaging: Enabling precise and vibrant printing on packaging materials, enhancing brand visibility. • Textiles: Facilitating the production of intricate designs on fabrics with rapid turnaround times. • Industrial Printing: Supporting the printing of functional materials and electronic components.

These applications underscore the versatility and adaptability of Dimatix’s inkjet technologies in meeting the diverse needs of modern industries.

Experience the FUJIFILM Dimatix Printheads at the FUJIFILM Technology Centre in Dubai.

Now you can experience all the innovations of FUJIFILM’s products at the FUJIFILM Technology Centre in Dubai – an immersive showcase of FUJIFILM’s latest technologies in printing, photography, medical imaging and more.

Visit us and discover more about the FUJIFILM Dimatix range of industrial printheads, and how they can maximise the quality and versatility of your printing.

FUJIFILM Dimatix – On the Cutting Edge of Printing

FUJIFILM Dimatix continues to lead the way in industrial inkjet printing, offering cutting-edge technologies that cater to the evolving needs of various industries. With innovations like the Samba™ printhead, Samba JPC™ UV inkjet modules, and SKYFIRE® SF600 printhead, Dimatix is well-positioned to drive the future of digital printing. As industries increasingly demand high-quality, efficient, and versatile printing solutions, FUJIFILMDimatix stands ready to meet these challenges head-on.

For more on FUJIFILM’s printhead technology, visit fujifilm.com/ae.